Cleaning Techniques

Over the last 20 years governments have created a situation in which companies such as Hot Dip Galvanizers have been forced to investigate the feasibility of different separation techniques. This has come about as a result of the increasingly stringent legislation concerning the disposal of virtually all kinds of waste products.

Additionally the world faces new problems like CO2 reduction and waste reduction.

CIC International cares about the future and future generations and has developed a full range of product to create a New Way of Galvanizing resulting in:

- No waste production

- CO2 free galvanizing

- Raw material reduction by introducing of the new alloy.

With the development of these “state-of-the-art” techniques, critical contamination levels have fallen dramatically. Whereas previously one spoke in terms of g/l, today critical limits are looked at in mg/l.

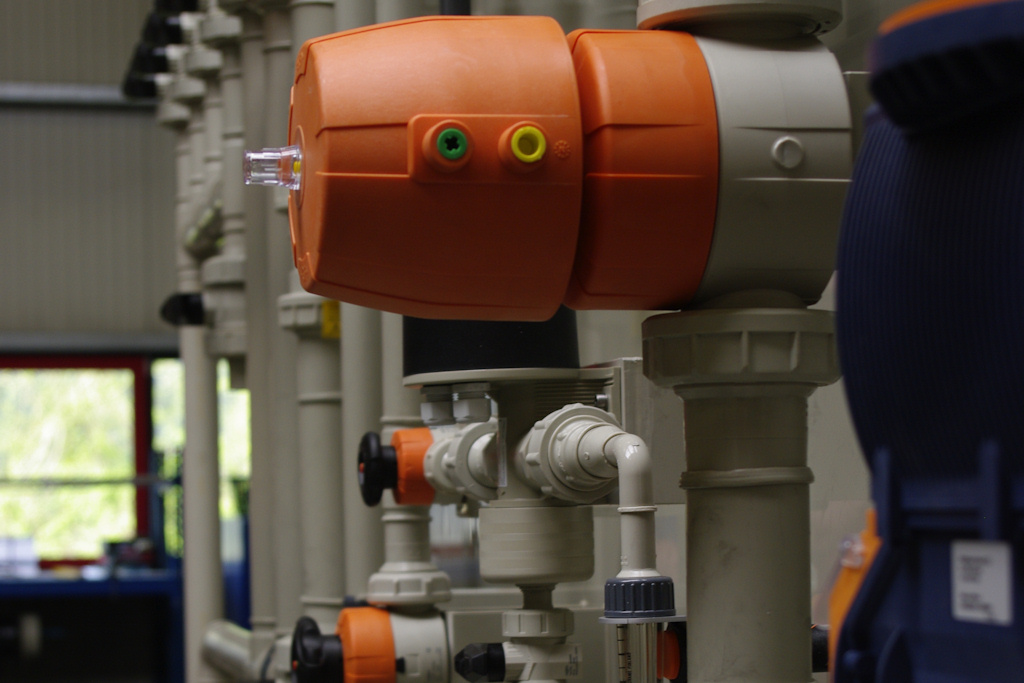

Over the last years CIC International has developed several processes capable of offering solutions for such “closed-loop” systems. The combinations of these different techniques give a “Total solution to the galvanizing and metal surface treatment industry”.

Examples that are unique in our product range:

- Rinse water treatment

- Zinc removal from pickling acid

- Air treatment of pickling fume

- Waste water treatment

- Dust filter for galvanizing

- Oil/fat removal from degreasing bath

- Zinc recovery systems and methods

- CO2 free galvanizing furnace

- Zinc reduction programs

- Kettle life time of > years

Just contact us and we will convince you